mirror of

https://github.com/odriverobotics/ODrive.git

synced 2026-02-06 23:41:53 +08:00

update READMEs to belong in new structure

This commit is contained in:

@@ -1,13 +1,4 @@

|

||||

# ODriveFirmware

|

||||

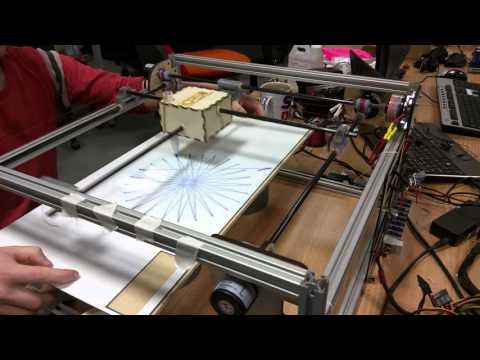

This project is all about accuratly driving brushless motors, for cheap. The aim is to make it possible to use inexpensive brushless motors in high performance robotics projects.

|

||||

Like this (click for video):

|

||||

[](https://www.youtube.com/watch?v=WT4E5nb3KtY)

|

||||

|

||||

This repository contains the firmware that runs on the board. The other related repositories are:

|

||||

* [ODriveHardware](https://github.com/madcowswe/ODriveHardware): Circuit board design. Also, the pinout from the microcontroller to the board is documented [here](https://docs.google.com/spreadsheets/d/1QXDCs1IRtUyG__M_9WruWOheywb-GhOwFtfPcHuN2Fg/edit?usp=sharing).

|

||||

* [ODrive](https://github.com/madcowswe/ODrive): Configuration and analysis scripts that runs on a PC.

|

||||

|

||||

There is also [ODriveFPGA](https://github.com/madcowswe/ODriveFPGA), which contains the FPGA logic and software that runs on the FPGA based ODrive. This is not currently in development, but may be resumed at some later date.

|

||||

|

||||

### Table of contents

|

||||

|

||||

@@ -25,16 +16,16 @@ There is also [ODriveFPGA](https://github.com/madcowswe/ODriveFPGA), which conta

|

||||

## Configuring parameters

|

||||

To correctly operate the ODrive, you need to supply some parameters. Some are mandatory, and if supplied incorrectly will cause the drive to malfunction. To get good performance you must also tune the drive.

|

||||

|

||||

The first thing to set is your board hardware version, located at the top of [Inc/main.h](https://github.com/madcowswe/ODriveFirmware/blob/master/Inc/main.h). If, for example, you are using the hardware: ODrive v3.2, then you should set it like this:

|

||||

The first thing to set is your board hardware version, located at the top of [Inc/main.h](Inc/main.h). If, for example, you are using the hardware: ODrive v3.2, then you should set it like this:

|

||||

```C

|

||||

#define HW_VERSION_MAJOR 3

|

||||

#define HW_VERSION_MINOR 2

|

||||

```

|

||||

|

||||

The rest of all the parameters are at the top of the [MotorControl/low_level.c](https://github.com/madcowswe/ODriveFirmware/blob/master/MotorControl/low_level.c) file. Please note that many parameters occur twice, once for each motor.

|

||||

The rest of all the parameters are at the top of the [MotorControl/low_level.c](MotorControl/low_level.c) file. Please note that many parameters occur twice, once for each motor.

|

||||

In it's current state, the motor structs contain both tuning parameters, meant to be set by the developer, and static variables, meant to be modified by the software. Unfortunatly these are mixed together right now, but cleaning this up is a high priority task.

|

||||

|

||||

It may be helpful to know that the entry point of each of the motor threads is `void motor_thread` at the bottom of [MotorControl/low_level.c](https://github.com/madcowswe/ODriveFirmware/blob/master/MotorControl/low_level.c). This is like `main` for each motor, and is probably where you should start reading the code.

|

||||

It may be helpful to know that the entry point of each of the motor threads is `void motor_thread` at the bottom of [MotorControl/low_level.c](MotorControl/low_level.c). This is like `main` for each motor, and is probably where you should start reading the code.

|

||||

|

||||

### Mandatory parameters

|

||||

You must set:

|

||||

@@ -169,7 +160,7 @@ For example

|

||||

* `g 1 3` will return the error status of M0

|

||||

* `g 1 7` will return the error status of M1

|

||||

|

||||

The error status corresponds to the [Error_t enum in low_level.h](https://github.com/madcowswe/ODriveFirmware/blob/f19f1b78de4bd917284ff95bc61ca616ca9bacc4/MotorControl/low_level.h#L17-L35).

|

||||

The error status corresponds to the [Error_t enum in low_level.h](MotorControl/low_level.h).

|

||||

|

||||

Note that the links in this section are to a specific commits to make sure that the line numbers are accurate. That is, they don't link to the newest master, but to an old version. Please check the corresponding lines in the code you are using. This is especially important to get the correct indicies in the exposed variable tables, and the error enum values.

|

||||

|

||||

|

||||

19

README.md

19

README.md

@@ -2,19 +2,12 @@

|

||||

|

||||

This project is all about accurately driving brushless motors, for cheap. The aim is to make it possible to use inexpensive brushless motors in high performance robotics projects, like [this](https://www.youtube.com/watch?v=WT4E5nb3KtY).

|

||||

|

||||

This repository contains configuration and analysis scripts that run on a PC. The other related repositories are:

|

||||

* [ODriveFirmware](https://github.com/madcowswe/ODriveFirmware): Firmware that runs on the board.

|

||||

* [ODriveHardware](https://github.com/madcowswe/ODriveHardware): Circuit board design.

|

||||

|

||||

There is also [ODriveFPGA](https://github.com/madcowswe/ODriveFPGA), which contains the FPGA logic and software that runs on the FPGA based ODrive. This is not currently in development, but may be resumed at some later date.

|

||||

|

||||

## Getting Started

|

||||

*References to hardware is with respect to v3.3. Other versions may still apply, but component designators may differ*

|

||||

|

||||

It is perfectly fine, and even recommended, to start testing with just a single motor and encoder.

|

||||

Make sure you have a good mechanical connection between the encdoer and the motor, slip can cause disasterous oscillations.

|

||||

All non-power I/O is 3.3V output and 5V tolerant on input, except:

|

||||

|

||||

* GPIO 3 and GPIO 4 are NOT 5V tolerant on ODrive v3.2 and earlier.

|

||||

|

||||

You need one or two [brushless motors](https://hackaday.io/project/11583-odrive-high-performance-motor-control/log/37666-hobby-motors-in-your-robots), [quadrature incremental encoder(s)](https://discourse.odriverobotics.com/t/which-encoders-to-choose/63/2), and a power resistor.

|

||||

@@ -32,9 +25,9 @@ The currently supported command modes are USB and step/direction.

|

||||

* If you are using step/direction, please see [setting up step/direction](#setting-up-stepdirection)

|

||||

|

||||

You can now:

|

||||

* [Download and build the firmware](https://github.com/madcowswe/ODriveFirmware)

|

||||

* [Configure the firmware parameters](https://github.com/madcowswe/ODriveFirmware#configuring-parameters)

|

||||

* [Flash the board](https://github.com/madcowswe/ODriveFirmware#flashing-the-firmware)

|

||||

* [Download and build the firmware](Firmware/README.md)

|

||||

* [Configure the firmware parameters](Firmware/README.md#configuring-parameters)

|

||||

* [Flash the board](Firmware/README.md#flashing-the-firmware)

|

||||

|

||||

### Startup procedure

|

||||

The startup procedure is demonstrated [here](https://www.youtube.com/watch?v=VCX1bA2xnuY).

|

||||

@@ -42,7 +35,7 @@ The startup procedure is demonstrated [here](https://www.youtube.com/watch?v=VCX

|

||||

Note: the rotor must be allowed to rotate without any biased load during startup. That means mass and weak friction loads are fine, but gravity or spring loads are not okay. Also note that in the video, the motors spin after initalisation, but in the current software the default behaviour is to do position control to position 0 (i.e. the position at startup)

|

||||

|

||||

### Sending commands

|

||||

Sending USB and UART commands is documented [here].(https://github.com/madcowswe/ODriveFirmware#communicating-over-usb-and-uart)

|

||||

Sending USB and UART commands is documented [here].(Firmware/README.md#communicating-over-usb-and-uart)

|

||||

|

||||

### Setting up UART

|

||||

Baud rate: 115200

|

||||

@@ -50,7 +43,7 @@ Pinout:

|

||||

* GPIO 1: Tx (connect to Rx of other device)

|

||||

* GPIO 2: Rx (connect to Tx of other device)

|

||||

|

||||

To enable UART mode for the GPIO, please see [Setting the GPIO mode](https://github.com/madcowswe/ODriveFirmware#configuring-parameters).

|

||||

To enable UART mode for the GPIO, please see [Setting the GPIO mode](Firmware/README.md#configuring-parameters).

|

||||

|

||||

### Setting up Step/Direction

|

||||

Pinout:

|

||||

@@ -62,7 +55,7 @@ Pinout:

|

||||

Please note that GPIO_3 and GPIO_4 are NOT 5v tolerant on ODrive v3.2 and earlier, so 3.3V signals only!

|

||||

ODrive v3.3 and onward have 5V tolerant GPIO pins.

|

||||

|

||||

To enable step/dir mode for the GPIO, please see [Setting the GPIO mode](https://github.com/madcowswe/ODriveFirmware#configuring-parameters).

|

||||

To enable step/dir mode for the GPIO, please see [Setting the GPIO mode](Firmware/README.md#configuring-parameters).

|

||||

|

||||

There is also a new config variable called `counts_per_step`, which specifies how many encoder counts a "step" corresponds to. It can be any floating point value.

|

||||

The maximum step rate is pending tests, but it should handle at least 16kHz. If you want's to test it, please be aware that the failure mode on too high step rates is expected to be that the motors shuts down and coasts.

|

||||

|

||||

Reference in New Issue

Block a user